25 Nov 2022

In recent years, many hospitals are starting to adopt their own oxygen supply model to effectively meet the oxygen consumption in medical care. PSA medical oxygen concentrator have the advantages of easy operation, fast oxygen production and high purity, which reduce the burden of medical work and facilitate medical staff and patients. In order to ensure the purity and efficiency of oxygen production, and to ensure the smooth operation of oxygen production in the process of mass use of medical oxygen concentrators, it is necessary to study and analyze the use and maintenance process, grasp the main points of problems that may occur in use, solve them in time and do the maintenance work later.

Working Principle Of PSA Oxygen Concentrator

The pressure swing adsorption (PSA) method is based on the different adsorption properties of molecular sieves for oxygen and nitrogen, and uses zeolite molecular sieves as adsorbents to separate oxygen and nitrogen in the air, thus selectively adsorbing oxygen in the air.

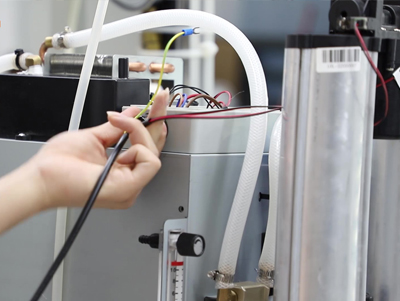

The composition of PSA oxygen equipment includes air compressor, main line filter, air balance tank, oxygen main unit, sterilization filter, oxygen tube installer and so on. In addition, the oxygen concentrator is equipped with two sets of 10 bottle manifolds as an emergency backup oxygen source. The molecular sieve is composed of many small particles, and the mass fraction and surface area of molecular sieve are not low, and the surface area of each gram of molecular sieve can reach 800~1000/g.

After the air is compressed, it enters the adsorption tower with zeolite molecular sieve after the air purification system removes impurities such as oil and water, solid dust, etc.The nitrogen, carbon dioxide and water vapor are adsorbed by the molecular sieve in large quantities, and oxygen is separated through the adsorbent due to the large diffusion rate, and oxygen is obtained directly from the compressed air.

To ensure a continuous and stable supply of oxygen, the plant is generally equipped with two or more adsorption towers, one for adsorption and the other for regeneration and recycling of the adsorbent. Switching of use is done at appropriate times to ensure continuous production of oxygen at concentrations between 90 and 94%.

Medical Oxygen Concentrator Use Maintenance Strategy

1. Oxygen concentrator use and maintenance

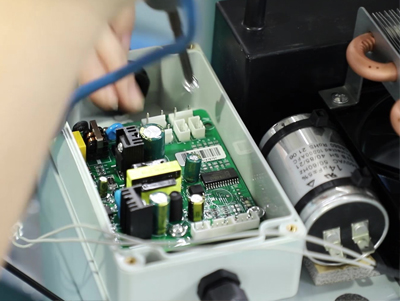

In normal air, the oxygen content is 21% and the nitrogen content is 78%. The function of the oxygen concentrator is to produce oxygen from the air and to separate and discharge the rest of the gas into the air. Medical oxygen concentrators are generally configured in two units, one is the main unit and the other is the secondary unit, which can be used to provide oxygen at the same time or separately.. Generally speaking, current medical oxygen concentrators have a very low probability of failure.The performance of the electronic board under normal conditions is relatively stable and will not fail.

The adsorption and resolution functions of the molecular sieve were affected, the oxygen concentrator is not operating effectively and the quality of the oxygen produced is not satisfactory. As the spool and diaphragm of the inlet valve, balancing valve and nitrogen discharge valve are moving parts, they are prone to rupture of the diaphragm and deformation of the spool tip during long working hours. As a result, the electromagnetic valve loses its normal closing function, which in turn affects the adsorption and analysis function of the molecular sieve to a certain extent, making the operation of the whole oxygen concentrator unsatisfactory. Therefore, in general, most of the malfunctions of the medical oxygen concentrator are due to this problem. If this problem is eliminated, then the oxygen concentrator should be checked thoroughly to find the cause of the malfunction. The molecular sieve is an important component of medical oxygen concentrators and plays an important role in the oxygen production process. It can be rendered useless by the environment, usage conditions, moisture, oil, etc

Maintenance treatment. Replace broken diaphragms and deformed spools in time to restore their closing function and prevent their influence on the adsorption and resolution function of molecular sieves, and it is necessary to maintain and replace molecular sieves regularly.

2.Air compressor use and maintenance

The failure phenomenon is as follows:

(1)During compressor start-up, the pressure does not reach the upper limit and remains loaded after a delay. The failure may be caused by a malfunctioning solenoid valve or a leak in the piping. There are two maintenance methods, one is to replace the solenoid valve if it fails, and the other is to replace the leaking hose with a leaking air hose if there is a leak in the pipe.

(2)The compressor air output process or the pressure is not higher than the normal value. The cause of the failure is an obstruction in the air filter element The maintenance method is to replace the filter element, replace the leaking hose with a leaking air hose, and replace the separator element if the oil/gas separator becomes clogged.

(3)The oil consumption is too large and the oil is carried in the discharge line. The reason for the failure is that the oil level is too high. First of all, check if there is too much oil or the oil added is not in accordance with the regulations or the oil-air separator is malfunctioning. Maintenance treatment to relieve the pressure and drain the oil to the correct level. If the added oil does not meet the regulations, replace it with a qualified oil. replace it with qualified oil. Check the oil and gas separator, and deal with any malfunction in time.

3. Summary

Medical oxygen concentrators play a pivotal role in medical rescue work, using them to produce high purity oxygen for patients to use. However, because of its long time working cycle, it will lead to various kinds of malfunctions, timely maintenance and treatment of malfunctions is the prerequisite to ensure the stable and safe work of medical oxygen concentrators.

Keywords: oxygen concentrator

Originally published 25 Nov 2022, updated 25 Nov 2022.