22 Apr 2022

The feasibility of molecular sieve oxygen production mechanism in oxygen supply in hospitals, based on the principle of molecular sieve pressure swing adsorption oxygen production technology and cryogenic oxygen production technology, compare the national regulations, safety, convenience and economy of the two oxygen production methods advantages and disadvantages in terms of. Compared with traditional steel cylinder oxygen supply and liquid oxygen centralized oxygen supply, molecular sieve oxygen concentrator has advanced technology, high degree of automation and long service life, and can avoid many shortcomings of traditional oxygen supply methods.

The role of oxygen

Oxygen is an indispensable medical material in modern hospitals, and plays an important role in life support, critical rescue and rehabilitation physiotherapy. With the continuous progress of preparation technology, hospital oxygen supply has been developed from cylinder oxygen supply, liquid oxygen centralized oxygen supply to molecular sieve oxygen concentrator oxygen supply.

At present, most hospitals in China still use cylinder oxygen supply or liquid oxygen centralized oxygen supply. The molecular sieve oxygen production technology uses air as raw material, which is convenient, safe and fast to use, which can avoid many problems of cylinder oxygen supply and liquid oxygen centralized oxygen supply. It is realize the autonomy of hospital oxygen supply, and choose a better oxygen supply method for the construction of modern hospitals.

While exploring the feasibility of molecular sieve oxygen concentrator mechanism in oxygen supply in hospitals, the principles of molecular sieve pressure swing adsorption oxygen production technology and cryogenic oxygen production technology were compared, and the national regulations, safety, convenience and requirements of the two oxygen production methods were compared. The advantages and disadvantages of economy and other aspects, and the prospect of its application.

Cryogenic oxygen production technology

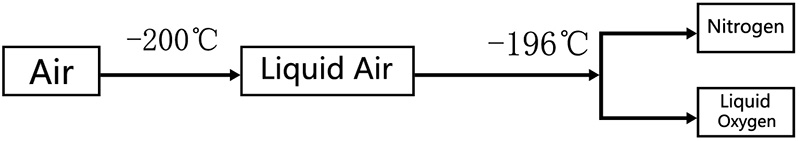

Cylinder oxygen supply and liquid oxygen centralized oxygen supply generally use cryogenic oxygen production technology. The preparation principle is: using air as raw material, through pretreatment, to remove impurities such as dust and water vapor, and then heat exchange to cool down the air to turn the air into liquid air, using the principle of different boiling points of nitrogen and oxygen, depressurizing and heating up to vaporize nitrogen to obtain liquid oxygen.

Cylinder oxygen supply is to put the prepared liquid oxygen into steel cylinders of different capacities under normal temperature and high pressure after vaporization and transport it to various departments for use. The liquid oxygen centralized oxygen supply technology is to fill the liquid oxygen into the special liquid oxygen storage tank installed in the hospital, and transport it to the special oxygen pipeline after decompression and vaporization used in clinical departments. Due to factors such as cost, technology, site, safety and labor, ordinary hospitals cannot perform cryogenic oxygen production. Usually, liquid oxygen must be regularly purchased from liquid oxygen manufacturers and sent to hospitals for filling by special liquid oxygen transport vehicles.

Molecular sieve oxygen concentrator principle

Molecular sieve pressure adsorption gas purification and separation technology is a technology developed with pollution control and environmental protection after the 1960s. It has been widely used in petrochemical, gas industry, steel industry and medical and health industries around the world and development. Molecular sieve is a crystalline aluminosilicate compound with a porous cage skeleton structure, which has good adsorption selectivity and efficient adsorption capacity. When the air flows through the adsorption tower equipped with molecular sieve, the molecular sieve preferentially adsorbs nitrogen molecules, while oxygen molecules. Molecules are rarely adsorbed. According to the unique selective adsorption characteristics of molecular sieves, it is possible to use molecular sieves to produce oxygen.

When the temperature is constant, the adsorption capacity of molecular sieve for nitrogen changes with the change of pressure. When the pressure increases, the adsorption capacity increases; when the pressure decreases, the adsorption capacity decreases. Through this feature, the adsorption and decompression of nitrogen can be realized. release process.

Molecular sieve oxygen concentrator working process

The ambient air passes through the coarse filter to remove large particles of solid impurities and enters the air compressor. The temperature of the compressed air rises. The high-temperature air first enters the air buffer tank, and then enters the freeze dryer after cooling. Precision filters remove dust that is to obtain dry and clean air.

The treated air is pressurized into the adsorption tower, nitrogen is adsorbed, oxygen flows into the oxygen buffer tank, and then decompressed, transported to the ward by pipeline, and the separated nitrogen is discharged outside. In order to continuously supply oxygen, molecular sieve oxygen concentrator are generally installed with more than 2 adsorption towers, which work alternately in the process of adsorbing nitrogen under pressure and releasing nitrogen under reduced pressure.

Keywords: oxygen concentrator

Originally published 22 Apr 2022, updated 22 Apr 2022.