06 May 2022

As a new type of oxygen production technology, molecular sieve oxygen concentrator is an energy-saving gas separation technology with low energy consumption and fast regeneration, especially suitable for applications in areas with inconvenient transportation and energy shortages. Molecular sieve pressure adsorption and purification technology is a major change in oxygen production technology. This technology is developing rapidly and will be more widely used in the future.

Advantages of molecular sieve oxygen concentrator

Compared with cryogenic oxygen production, molecular sieve oxygen production has greater advantages in terms of safety, convenience and economy. The oxygen content of medical oxygen shall not be less than 99.5%. The oxygen concentration obtained by the molecular sieve oxygen concentrator can reach 96%. Due to the slight loss of oxygen in the pipeline and interface during use, compared with the centralized oxygen supply of the steel cylinder and the liquid oxygen, the molecular sieve oxygen concentrator is easier to meet the relevant regulations.

In addition, the liquid oxygen storage tank for centralized oxygen supply is a high-pressure container, and it is necessary to enforce fire regulations. It is installed outdoors on the ground. For general hospitals, it is not only difficult to achieve, but also wastes a lot of land resources; the molecular sieve oxygen concentrator belongs to Class I type B permanent installation Equipment, the equipment has low working pressure, no fire protection requirements, can be installed indoors, and has a small area.

Cylinder oxygen supply method the compressed oxygen pressure in the bottle is extremely high. During the process of transportation, handling and storage, improper operation and management are prone to explosion and high risk. Liquid oxygen centralized oxygen supply method Liquid oxygen is extremely low temperature, and accidental contact during vaporization will cause serious injury to personnel; the oxygen storage capacity of the liquid oxygen tank is extremely large,the explosion risk is great; in addition, the liquid oxygen tank needs to be evacuated regularly, and the operator is at great risk. Molecular sieve oxygen concentrator works at normal temperature and low pressure.

The prepared oxygen is directly transported to the ward by the pipeline, and there is no transportation, filling and storage, and the safety is high. In the oxygen supply of steel cylinders, the amount of oxygen stored in a single cylinder is small, and the oxygen cylinders need to be replaced frequently. The purchase, transportation, storage and custody are complicated and cumbersome, and consume a lot of manpower and material resources. Liquid oxygen centralized oxygen supply requires regular purchase of liquid oxygen from professional oxygen producers, and transportation and filling by special high-pressure tank trucks. Therefore, the procurement cycle takes 5 to 7 days and the oxygen station needs to be equipped with more management and maintenance personnel.

For the above two oxygen supply methods, oxygen preparation is not completed in the hospital. It takes a certain time from purchase to use, and is affected by weather and traffic. In case of emergencies, it is easy to cause difficulties in hospital oxygen use. The molecular sieve oxygen concentrator is installed in the hospital and uses air as the raw material. It is convenient and fast to operate, and it is self-produced and used. Especially in small and medium-sized cities that lack liquid oxygen manufacturers, it is more convenient.

The equipment is controlled by a microcomputer, and the operation is simple and convenient. It only requires less management personnel. Multiple adsorption towers work in turn. The failure of one of them does not affect the overall oxygen supply, which can save a lot of manpower and material resources. The hospital can choose to purchase directly on the introduction of molecular sieve oxygen concentrators. There are two ways to launch with cooperation.

The development prospect of molecular sieve oxygen concentrator

As a new type of oxygen production technology, molecular sieve oxygen concentrator is an energy-saving gas separation technology with low energy consumption and fast regeneration, especially suitable for applications in areas with inconvenient transportation and energy shortages. With the advancement of science and technology, molecular sieve oxygen concentrators can be further developed in the following aspects.

The oxygen concentration obtained by the molecular sieve oxygen production mechanism is (96±3)%. Compared with the 99.5% oxygen concentration of the cryogenic oxygen production technology, the oxygen concentration of molecular sieve oxygen production is somewhat lacking. With the development of the material industry and the application of new adsorption materials, the adsorption performance of molecular sieves will be improved, and the oxygen concentration produced will be higher and higher, making it possible to reach the oxygen concentration produced by the cryogenic oxygen production technology.

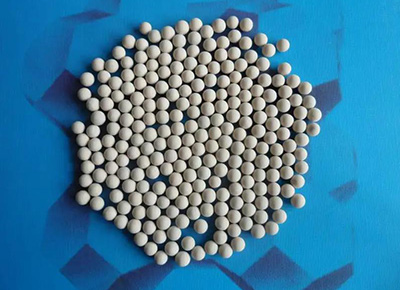

Molecular sieve oxygen concentrator generally uses zeolite molecular sieve as adsorbent. The service life of zeolite molecular sieve is 1 to 2 years, and it is particularly sensitive to moisture. The amount of water in the air will directly affect its service life. Although manufacturers generally promise to replace molecular sieves free of charge within 10 years, the development of molecular sieve materials with long service life and high adaptability will certainly greatly promote the development and application of molecular sieve oxygen concentrators.

Compared with the centralized oxygen supply of liquid oxygen, the installed capacity and area of the molecular sieve oxygen concentrator have been greatly reduced, but it still needs to be placed in a special machine room, occupying a certain area. At present, the domestic molecular sieve oxygen concentrators on the market are highly portable, but the oxygen concentrator supply oxygen purity level can only reach about 80%, which cannot meet the requirements of the specified molecular sieve oxygen concentration level of 90%. Therefore, the development of molecular sieve oxygen concentrators that meet relevant regulations and are highly portable is one of the development directions of the future.

Outlook the future of oxygen concentrator

Molecular sieve pressure adsorption and purification technology is a major change in oxygen production technology, which is developing rapidly and will be more widely used in the future. Compared with traditional steel cylinder oxygen supply and liquid oxygen centralized oxygen supply, molecular sieve oxygen production technology is safe to use, easy to operate, less economical investment and high degree of automation. At present, some large and medium-sized hospitals have adopted this method to supply oxygen. With the development of science and technology, molecular sieve oxygen production technology will continue to develop and improve, so that the obtained oxygen concentration level is higher and purer, the equipment life is longer, the degree of automation is higher, and the portability is better, providing better support for the construction of modern hospitals.

Keywords: oxygen concentrator

Originally published 06 May 2022, updated 06 May 2022.