13 Jan 2023

For patients with all types of hypoxic diseases, an important adjunct to treatment is frequent supplemental oxygen.In large hospitals, inpatients can easily receive oxygen from bedside oxygen concentrator. However, in small hospitals and at home, people are restricted by many conditions and it is very inconvenient to take oxygen.Medical oxygen concentrators that can work safely and economically and continuously have become an urgent need for patients.

Technology Status of Medical Health Care Oxygen Concentrator

Medical health care oxygen machine is the use of modern gas separation technology which is Pressure Swing Adsorption technology to produce oxygen.

Along with the rapid development of the global economy and the continuous improvement of people's living conditions, people are more concerned about the quality of their living environment and their own health.Especially the majority of residents living in the modern metropolis. how to take care of the health of the heart and brain in a stressful and busy life? How to enjoy fresh and pure even in the countryside in time.Variable pressure adsorption medical health care oxygen generators can address the needs of patients with oxygen deficiency diseases.

The oxygen concentrator cores molecular sieve

Physics tells us that when a gas or liquid moves to the surface of a solid.The gas or liquid molecules will then temporarily stay on the solid surface.Resulting in more gas molecules or liquid molecules on the surface of the solid that is the surface concentration is increased.

In science, this phenomenon of increased concentration of gas or liquid molecules on a solid surface is known as adsorption.In order to take full advantage of the adsorption phenomenon, substances called molecular sieves were discovered.It is a class of solid particulate matter with uniform micropores and very tiny pore size.It is possible to sieve gas molecules of different sizes according to their effective pore size.

For practical applications, molecular sieves require good selectivity and adsorption capacity, a large surface and a porous structure.In addition, the molecular sieve is required to have a high mechanical strength in order to adapt to the process needs.Taking gas separation as an example, different varieties of synthetic zeolite molecular sieves can be used to produce oxygen, nitrogen, nitrogen gas,etc.respectively.

The Development of oxygen production by Pressure Swing Adsorption

Pressure Swing Adsorption gas separation technology was first developed in 1959. Corporation in the USA.The application of PSA for gas separation developed rapidly in the 1960s after the use of PSA units for gas separation by the United States.

Currently, PSA installations are polarizing towards large and small size.In terms of small size, we have launched medical health care oxygen generators suitable for personal use.Such as the CP101 Medical Health Oxygen Concentrator manufactured by Foshan Mic Medical Technology Co. Ltd.Oxygen concentration up to 96% and oxygen flow is 10L.

The basic principle of oxygen production by variable pressure adsorption is to use the zeolite molecular sieve to adsorb different oxygen and nitrogen components in the air.Selective adsorption of nitrogen in air and the ability to adsorb nitrogen increases as the partial pressure of nitrogen increases.Adsorption at higher pressure by changing the adsorption operating pressure.Reduce the pressure to make it desorption, to achieve the purpose of separating oxygen and nitrogen in the air.

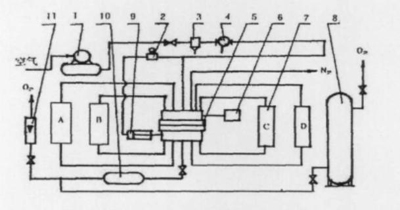

Using the principle of health care system, take the following medical health care oxygen generator as an example, the process flow is shown in Figure 1.1

Process flow of medical molecular sieve oxygen generator equipmen

1. Oil-Free Air Compressor

2. Solenoid Valve

3. Separator

4. Water Separation Filter

5. Multi-rotary distribution valve

6. Program Controller

7. Adsorption tower

8. Large oxygen storage tank

9. Cylinder

10. Small oxygen storage tank

11. Flow meter

Raw air is compressed by air compressor to about 05MPa.It enters the separator of the main body of the oxygen generator and is then dewatered by the water separator.After further dewatering and filtering, a very small amount of compressed air enters the cylinder through the solenoid valve according to the instructions issued by the program controller.Acts as a motive force to drive the multi-way rotary distribution valve.The majority of the compressed air is directed through a multi-way rotary distribution valve to each of the four adsorption columns filled with 5A molecular sieves according to a set program.

The oxygen and nitrogen gases in the compressed air are separated in the adsorption tower through 12 transformation processes.The nitrogen is drawn from the bottom of the adsorption tower and evacuated through a multi-way rotary distribution valve.Oxygen flows out from the top of the adsorption tower and enters the small oxygen storage tank through a multi-way rotary distribution valve, except for a small portion of oxygen recharge for oxygen charging of another adsorption tower.Most of the oxygen enters the oxygen storage tank as product gas for use.The oxygen output of this oxygen generation equipment can be designed according to the user's needs. The oxygen concentration is 96%. The content of other components are in accordance with the requirements of medical oxygen.

There are criteria for the selection of air compressors for oxygen production, first of all, the compressor should be oil-free lubrication.The molecular sieve is afraid of being poisoned and requires oil-free air.So the compressor must be oil-free lubrication type.For piston type, the US data shows that the frictional failure time is only guaranteed for 4000 hours of continuous operation.This does not meet the need for continuous oxygen supply to the patient.Secondly, the amount of air to be appropriate, a certain purity of oxygen certain adsorption type of the amount of raw air required.The air-to-oxygen ratio has a certain range, too big and too small can not, which is determined by the adsorption performance.

Keywords: oxygen concentrator

Originally published 13 Jan 2023, updated 13 Jan 2023.